Drying ovens are used a lot in manufacturing fields, drying ovens usually have 2 main components, namely the heating part (Heater) and the place to store dried products (Drying room), depending on the form, product, field. The area where the heating element can be located directly or outside the drying chamber is suitable for the intended use.

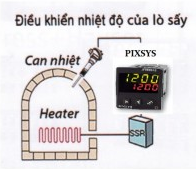

It can be said that the temperature plays a role in determining the quality of the product after drying, so the correct temperature adjustment is the most important. To do that we need the support of measuring devices, which are installed into a system according to the simplified diagram as follows:

- Temperature sensor: consists of a heat probe located in the drying oven, subject to direct impact heat. The onion head is usually attached to the upper part of the oven, this part will be responsible for taking temperature parameters from the signal transducer to PIXSYS.

- PID control: the part that receives the temperature signal from the thermocouple, displays the parameters and processes the information, adjusts the input signal to the SSR

- SSR (relay – solid state relay) connecting part between Heater and Pixsys, has the function of stabilizing current, switching thermistor, acting as a contactor (magnetic starter)

- Heater: the heating element for the oven, receiving a signal from the SSR to increase or decrease the temperature. This part can be located inside the oven as shown, or outside, depending on the type of oven

Because the drying oven has many types, the drying temperature is also different, so it is indispensable to choose the right thermometer and probe, we can refer to some of the following types:

- Temperature below 600 oC: PT100 of H.Heinz-Germany, Pr Electronics- Denmark

- Temperature over 600 oC: Themocouple , PT1000 of H.Heinz-Germany, Pr electronics – Denmark