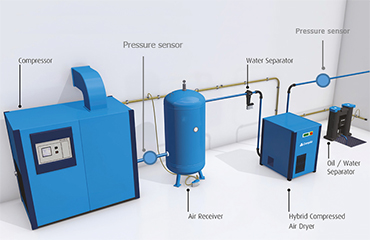

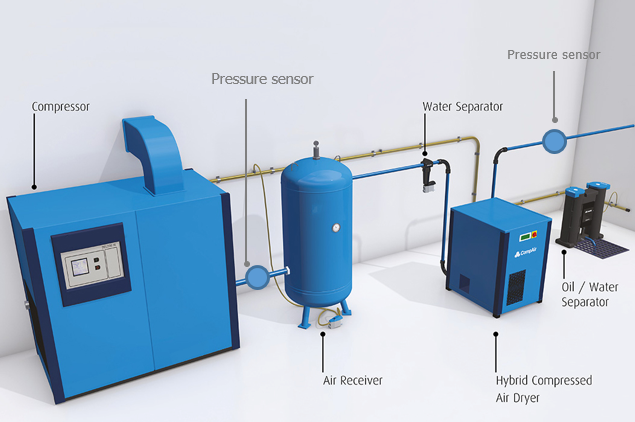

The air compressor is responsible for sucking the air out of the environment and then compressing it and putting it into the storage tanks and transmitting it to the places where it needs to be used, such as cleaning dust, operating mechanism-moving like a robot or sources of control for screw-drivers,…

During operation, we need to monitor and control compressed air pressure:

Purpose: to ensure system safety, to operate the compressor correctly, to minimize air loss that affects business efficiency.

Usually we will immediately think of a pneumatic pressure gauge.

- Pressure Gauges

- Pressure Switches

- Pressure Sensors

Here, Viet Nhat company will introduce to you about the above 3 sets of equipment in terms of properties as well as how it works effectively:

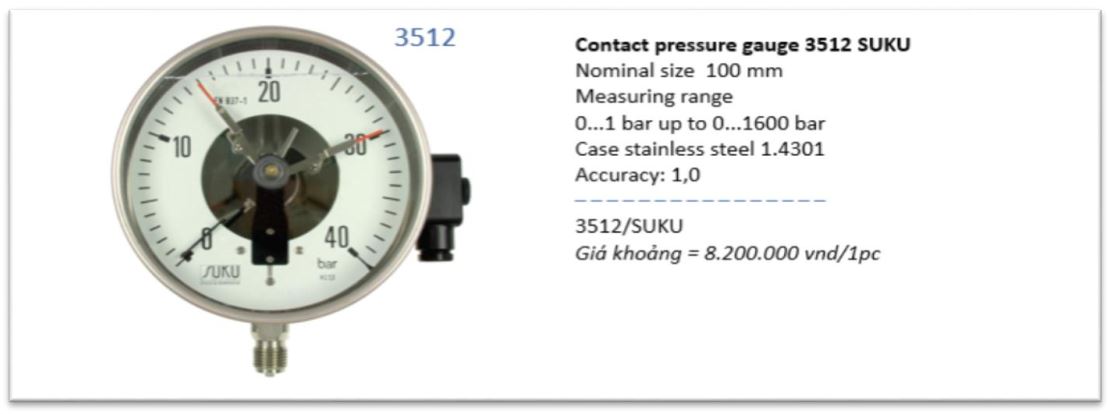

SUKU 3512 – contact pressure gauge

A device commonly found in pressurized systems, but this type of meter features an additional contact and usually 1 or 2 NO/NC contacts.

Work:

With the dial showing the measured pressure value on the scale intuitively, even when the system loses power and is at the red needle positions (set point), we can set the impact thresholds. Output contact when the gas pressure inside the pipeline reaches this value to control the opening and closing of the compressor shut-off valve or to warn the underpressure – full pressure – overpressure alarm system…

Advantages:

- Easy to install.

- Easy to install and use.

- Withstands harsh environments.

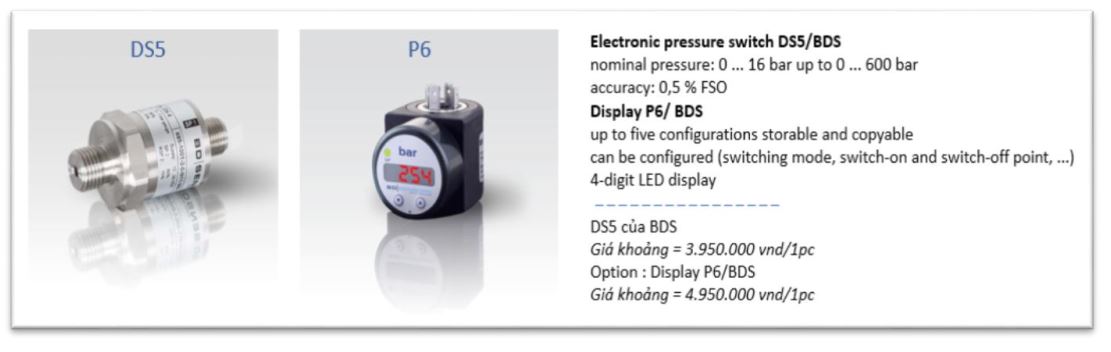

With this unit we can choose up to 2 PNP output signals with a local display unit and the P6 can set thresholds for the NO or NC output signal.

Work:

Installed directly at the compressor position to directly control the compressor opening and closing pressurized air supply or on the pipeline to control the output pressure used as a warning signal of underpressure or overpressure, besides setting the time The point of impact of the signal is very easy through the display P6 which will make the operation more efficient.

Advantages:

- High precision.

- Fast response time.

- Easy to set the oil pressure threshold.

- Compact device for easy installation.

- Has LED digital display

- Withstand high pressure

BD Sensor 26,600 pressure sensor and PR 4131+ PRelectronics 4501 display screen

Similar to the method of using pressure contact as above, we have the pressure sensor BDs 26,600 and the controller PR 4131+4501 also work the same, but here with the PR 4131 unit will give output signal in the form of relay. .

Work:

The pressure sensor will measure the pipeline pressure and transmit a signal to the controller Pr 4131 with 2 relays. We can set the time and the time of impact for these 2 relays through the PR 4501 monitor and other sensors. Pipeline value will be displayed at this screen making it easier for the operator.

Especially in high places or in equipment with not much space, installing BDs 26,600 pressure sensor and sending the signal outside to monitor the operation is a quite optimal solution.

Advantages:

- High precision

- Fast response time

- Has LED digital display

- Can be used in fire-safe environments.

- Does not generate sparks like a normal pressure switch

- Limit the risk of overvoltage affecting operating structures and people.

Thus, with 3 methods and 3 groups of equipment above distributed by Viet Nhat, we will definitely optimize and completely replace the devices that customers are using.

To easily choose and balance the cost, please send our customers the basic parameters along with the reference prices for our 3 sets of products as below: