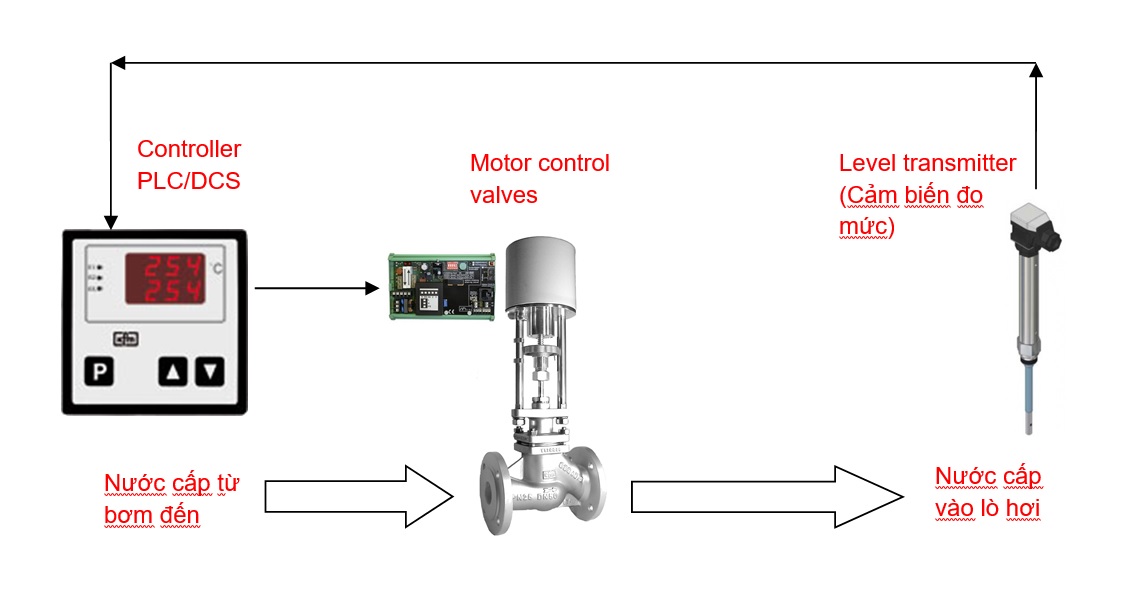

Principle of operation of the continuous water supply system for the boiler:

For boilers with a capacity of less than 5 ton/h We only need a water pump to fill the boiler with water, but for boilers with a capacity of over 5 ton/h, we need to use this principle to For water supply to the boiler, the system includes devices such as level transmitters, PID controllers, and linear valves controlled by electric motors. Normally We should use PI or PD mode of the controller to make the adjustment simple but effective as desired.

Specifications of devices:

- Level transmitter (continuous level sensor)

Measuring principle: capacitance, radar, ..

Output: 4 – 20 mA

Mechanical connection: G1.1/2”, or G1”

- Controller (PID controller)

Input: 4-20 mA

Output: 4-20 mA

24 VDC or 220 VAC power supply (depending on demand)

size: 48x48mm, or 48x96mm, 96x96mm (normally use size 96x96mm)

- Motor control valve (motor control valve)

Input: 4-20 mA

size : DN20, DN25,,…DN250mm (depending on use needs to choose)

Pressure: PN16, PN25, PN40 (depending on the use needs to choose)

closing pressure: 5 bar, 9 bar, 20 bar,..depending on the working pressure on the pipeline to the valve

Application of the principle of continuous water supply.

We often use the principle of continuous water supply for boilers with a capacity of over 5 tons/h. For the purpose of protecting the furnace body